By Robert Tate, Automotive Historian and Researcher

Images Courtesy of the Chrysler Archives

Published 05.01.2019

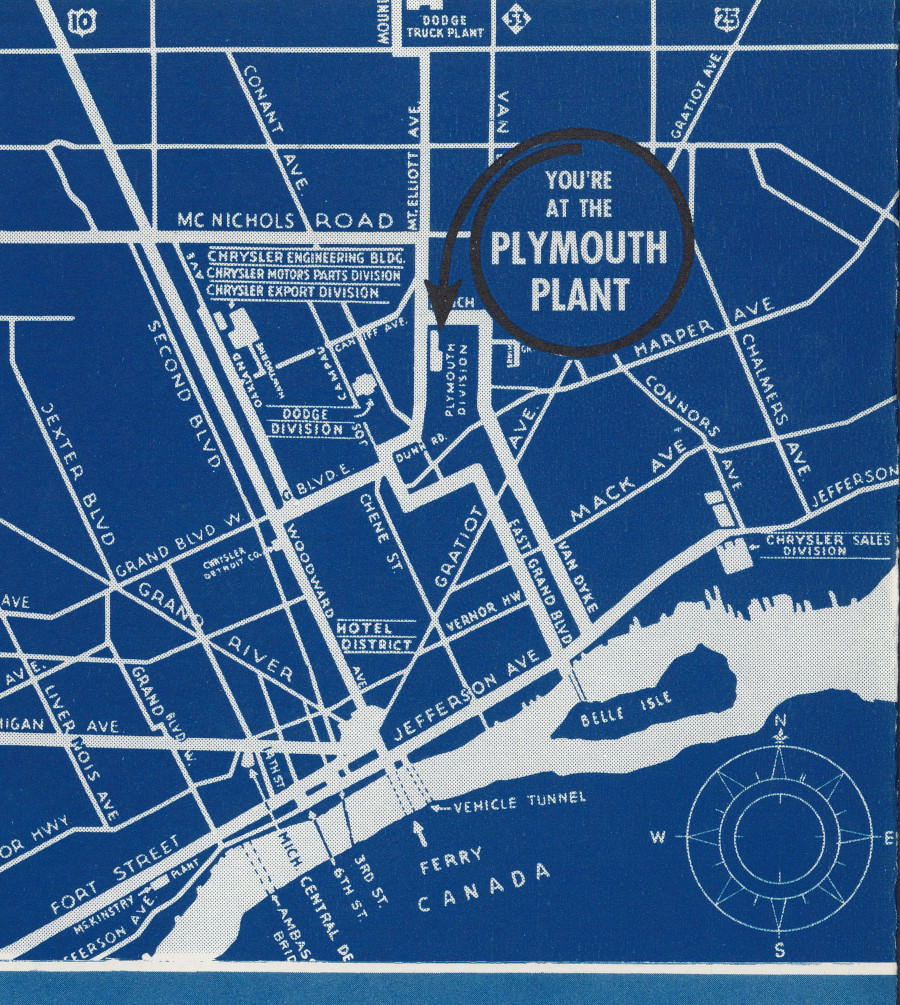

Map of Detroit including the Plymouth plant, 1941 (Chrysler Archives)

Map of Detroit including the Plymouth plant, 1941 (Chrysler Archives)

In 1941, before wartime production had begun, many men and women from the Detroit area worked in one of the largest automotive manufacturing plants in the world that was not part of Ford and General Motors.

During the early days, the Plymouth plant was recognized as one of the world’s most modern automobile facilities. The factory was in the Detroit area with 26 acres of manufacturing floor space. The advertising slogan at the time said, “You’ll see Plymouths built from start to finish.”

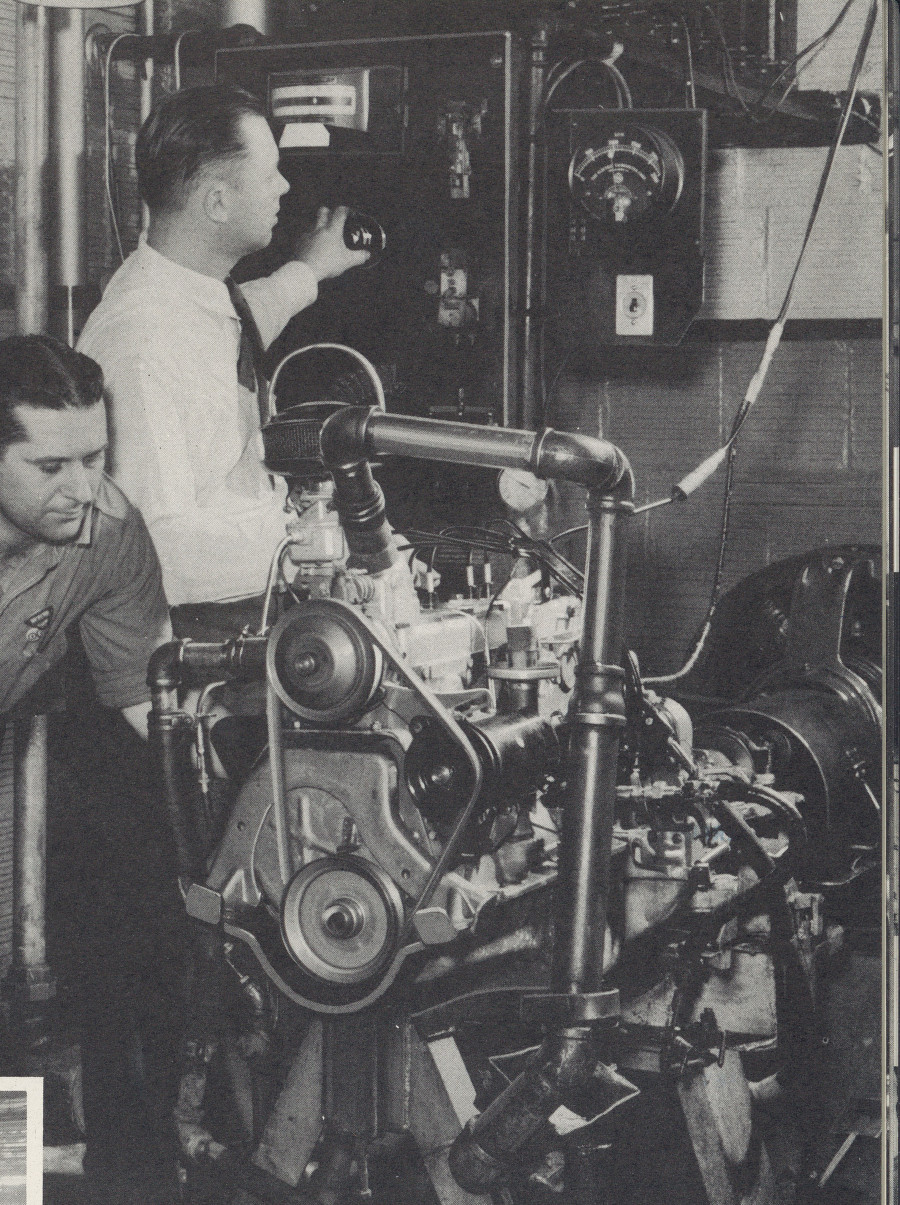

Plymouth's Detroit factory, 1941 (Chrysler Archives)

Plymouth's Detroit factory, 1941 (Chrysler Archives)

All of the bodies were made of steel and later fitted with instruments and other appointments that made an automobile complete. In 1941, labor strikes hampered the manufacturing process of some parts, but production was not effectively interrupted. That year, the Plymouth still held its position as the third biggest producer in the industry based on sales.

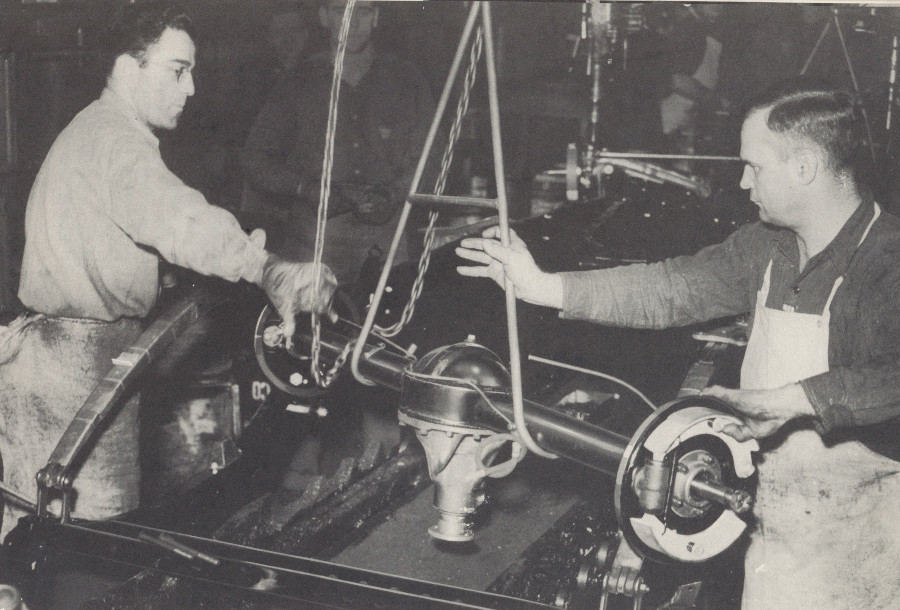

Plymouth's Detroit factory, 1941 (Chrysler Archives)

Plymouth's Detroit factory, 1941 (Chrysler Archives)

The 1940-41 Plymouth models were an instant success with the buying consumer. At the start of the manufacturing process, workers would telegraph parts orders to stations along the assembly line for a car’s frame and body. The bodies would travel on many conveyors for the next assembly operation. In 1941, Plymouth had several lines that carried the frames with the body hardware installed, across to the main assembly line where the bodies would receive fenders, batteries and additional trim parts. Then, instrument panels, shock absorbers and headlamps were added, and the 1941 Plymouths took shape.

One of the main features of the Plymouth manufacturing process was engine testing. Plymouth engines were tested for their required horsepower. The engine testing was called a “running in,” and after being “run in,” each engine was tested for horsepower, which the workers called a dynamometer test. From frame to a finished product, it took 50 minutes to manufacture a Plymouth product in 1941. Today, automakers have factory computers that reduce assembly time.

The chassis assembly was another important part of the manufacturing process. It took 12 minutes for the painted chassis to pass through an oven where the paint was thoroughly baked before further assembly line operations. From shaping brake tubing to mounting wheels and tires each consisting of wheel, tire and brake drum were assembled as single units before being mounted on the car. Installing steering and shift columns included steering gear mechanism along with a steering wheel gearshift were installed.

In 1941, before a new car was driven off the assembly line, Plymouth models would go through a series of tests before they were sold to the public. Even before moving off the assembly line under its own power for the first time, each model would be tested and inspected. For example, the “roller test” was a floor machine that held the front blocks in place while the rear wheels would drive on heavy rollers set in the floor. The factory employee could shift through low, second and high gears, testing the transmission and rear axle, and finally the hydraulic and braking systems. Other tests included sealed beam headlights, upholstery, paint, hinges and locks.

In conclusion, the 1941 Plymouths were assembled under one roof, and the men and women of Michigan helped put America on wheels.

Bibliography

Butler, Don. “The Plymouth and DeSoto Story.” Crestline Publishing, 1978.

Szudarek, Robert G. “How Detroit Became the Automotive Capital 100th Anniversary.” 1996.

Vertical file – “Plymouth Factory History.” The National Automotive History Collection.