By Robert Tate, Automotive Historian and Researcher

Images courtesy of Robert Tate’s collection

Posted: 01.17.2017

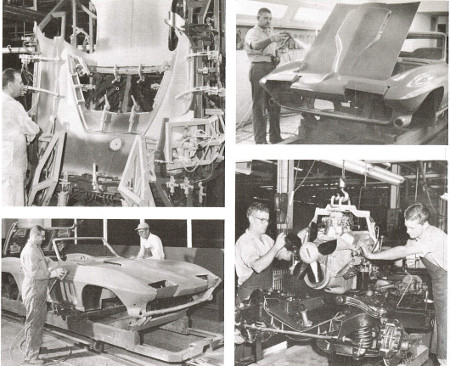

Before the days of computers and factory automation robots, Chevrolet manufactured its great looking automobiles through the handcrafted talent of the men and women who made up the creative strength of the automotive industry.

It was these men and women in the automotive factories that helped to place America on wheels and who helped to shape this great country. The growth of the automobile and its workers created the American middle class providing economic stability for the nation as a whole.

On a historical note, Chevrolet had many great operating manufacturing facilities which many Americans today have some kind of historical, familial connection. These families today have great and fond memories of past generations who were family members who represented that shining example of the American dream.

The Chevrolet brand and its factories were very much a part of this American culture. For example, Chevrolet had opened many new and great factories all over the United States like the new South Gate plant located in southern California. In the beginning, these new facilities helped to build and manufacture the all-new 1936 Chevrolet automobiles.

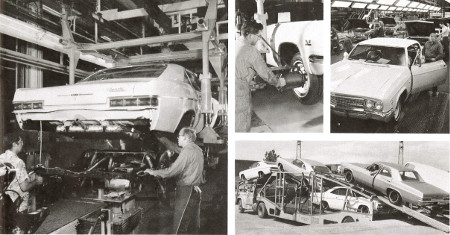

This story, however, is about the manufacturing plants that produced the1966 Chevrolet automobiles as well as the 1966 Corvette models. In 1966, the Lordstown, Ohio, assembly plant manufactured a new 1966 Chevrolet model. The 1966 Chevrolet models were great looking vehicles and were very popular among the American consumers creating great sales volume for General Motors. It was a great place to work with the assembly line area offering its factory workers 1.9 million square foot of plant space in 1966. In 1966, a production rate was five vehicles per hour, however later that year, the manufacturing process was increased to 60 cars per hour.

It was the best of times for many factory employees with many great opportunities for career development and great benefits with a great salary as well. Some of the other General Motors-Chevrolet assembly plants included facilities in Flint, Michigan; Norwood, Ohio; Tarrytown, New York; and Indianapolis, Indiana along with many other plants that helped to create and manufacture the 1966 Chevrolet models. From receiving fittings and final trim, the 1966 Chevrolet models were a work of precise quality and tooling of which many of the factory assembling workers were a part off. Chevrolet assembly workers also knew that the component parts of a car had to be available at precisely the right time to keep the cars rolling off the lines.

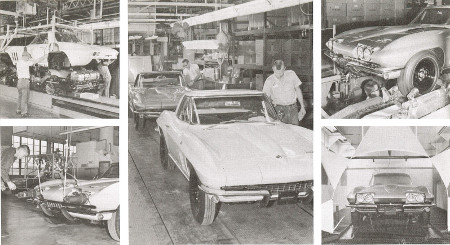

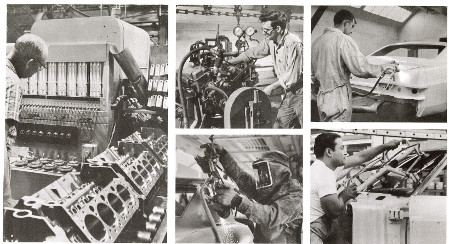

The 1966 Corvette models were manufactured at the St. Louis, Mo. assembly plant in 1966. General Motors produced 27,720 models for the year and most importantly, the models were very popular among consumers. On a historical note, the first Corvette models for 1953 were manufactured at the Flint, Michigan assembly plant and later the models were manufactured at the St. Louis Chevrolet plant in December 1953-54.

Sports car fans thoroughly enjoyed the first Corvette models but had to wait in line to purchase one. The 1966 Corvette models during the assembly process by the men and women received many highly specialized production methods. No other sports car was built and manufactured like the popular 1966 Corvette models. In the beginning, the St Louis plant was the only plastic auto body assembly line in the world that manufactured the great looking Corvette models later General Motors would move the Corvette assembly to the Bowling Green manufacturing location.